Polycarbonate vs. Polypropylene: Which is Better in Jug and Container Applications?

11 March 2021

To some, plastic is just plastic, but that’s simply not the case. Each has its own properties, which make one or another the best material for an application. In particular, many do not understand the differences between polycarbonate and polypropylene. These plastics should not be used interchangeably. Each has its own set of characteristics that make them unique, and deciding between the two is important for any manufacturer.

Both of these plastics are made by a process called polymerisation – the forming of macromolecule polymers out of small molecules called monomers. Polycarbonates are made from Bisphenol A and phosgene monomers using a process called step-growth polymerisation. On the other hand, chain growth polymerisation transforms propylene monomers into polypropylene.

What is Polycarbonate?

Polycarbonates are a group of thermoplastic polymers that are strong, durable and long-lasting. They can be made optically clear and are shatter resistant. Polycarbonate is rigid, resists staining and can withstand temperatures from -40℃ to + 100℃ (up to 190℃ in high-heat polycarbonate). High-heat polycarbonate is usually amber or black in colour.

Because of its toughness, transparency and temperature tolerance, polycarbonate is chosen for both indoor and outdoor use. It is commonly used to produce:

- Consumer products like sunglasses, CDs/DVDs, face shields and safety goggles.

- Appliances – its strength and versatility allow it to be used in the manufacture of many appliances and consumer electronics.

- Automotive – cars wouldn’t look like they do without polycarbonate mouldings; it’s light, strong and easily moulded.

- Medical – polycarbonate’s clarity makes it the perfect material for many medical uses, from surgical instruments to blood filters.

- Building and construction – polycarbonate is often used as an alternative to glass as it is light and easy to work with.

What are the Benefits of Using Polycarbonate for Jug and Container Applications?

Benefits of polycarbonate include:

- Its high-impact resistance makes it almost unbreakable in use.

- It is completely clear, which makes it easy to use for measuring and to see what’s inside.

- You can expect polycarbonate to last for 25 years without deteriorating.

- It is flame retardant.

- Polycarbonate has good abrasion resistance, so it will be long-lasting.

What is Polypropylene?

Polypropylene is also a thermoplastic polymer but differs in its properties from polycarbonates. It is translucent, impact-resistant and robust, and can stand temperatures of between 0℃ and +90℃. Below freezing, polypropylene becomes brittle, and above 90℃, its strength may be compromised.

This plastic can be coloured for different uses and is both dishwasher-safe and microwavable. Polypropylene is often made into fibre by a standard melt spinning process.

Common uses of polypropylene include:

- Plastic parts – from automotive to toys.

- Luggage – Many suitcase manufacturers rely on polypropylene.

- Rope – because of its fibre-like qualities, polypropylene is often used for rope and cordage.

- Carpets – carpeting and fabrics both benefit from this plastic, as do woven bags, packaging and filters.

- Medical – the medical and scientific worlds would be hard-pressed to do without polypropylene .

What are the Benefits of Polypropylene for Jug and Container Applications?

Benefits of polypropylene include:

- It is light and flexible.

- It is resistant to damage by chemicals.

- Newer versions have an elastic property making polypropylene even more versatile.

- It costs less to manufacture, so it’s more affordable for large-scale operations.

- It’s BPA-free.

- It is unaffected by bacteria and mold.

- It can be easily coloured for distinction in kitchen applications or branding.

Both plastics have their place within jug and container manufacturing, but which you choose will depend on your individual needs. Here at Pro-Measures, we make all our products from food-grade polypropylene for maximum versatility and easy branding. Not only is polypropylene recyclable, but we ensure that all our packaging is environmentally friendly as well, so we’re the ideal choice for the eco-conscious brand.

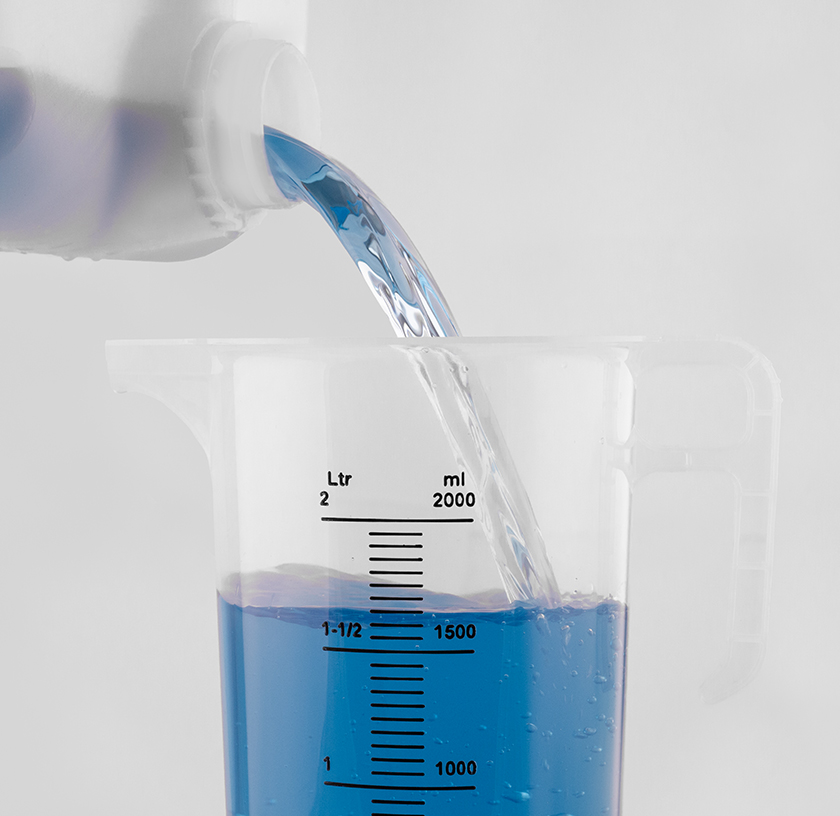

Polypropylene is the perfect material for our products, allowing us to produce high-quality measuring jugs, buckets, cylinders and scoops. They are tough, durable, and a cost-effective solution to our customers’ needs, whether in the food industry, chemicals or agriculture. Click here to learn more.

Each has its own properties, which make one or another the best material for an application. In particular, many do not understand the differences between polycarbonate and polypropylene. These plastics should not be used interchangeably. Each has its own set of characteristics that make them unique, and deciding between the two is important for any manufacturer.

Both of these plastics are made by a process called polymerisation – the forming of macromolecule polymers out of small molecules called monomers. Polycarbonates are made from Bisphenol A and phosgene monomers using a process called step-growth polymerisation. On the other hand, chain growth polymerisation transforms propylene monomers into polypropylene.

What is Polycarbonate?

Polycarbonates are a group of thermoplastic polymers that are strong, durable and long-lasting. They can be made optically clear and are shatter resistant. Polycarbonate is rigid, resists staining and can withstand temperatures from -40℃ to + 100℃ (up to 190℃ in high-heat polycarbonate). High-heat polycarbonate is usually amber or black in colour.

Because of its toughness, transparency and temperature tolerance, polycarbonate is chosen for both indoor and outdoor use. It is commonly used to produce:

- Consumer products like sunglasses, CDs/DVDs, face shields and safety goggles.

- Appliances – its strength and versatility allow it to be used in the manufacture of many appliances and consumer electronics.

- Automotive – cars wouldn’t look like they do without polycarbonate mouldings; it’s light, strong and easily moulded.

- Medical – polycarbonate’s clarity makes it the perfect material for many medical uses, from surgical instruments to blood filters.

- Building and construction – polycarbonate is often used as an alternative to glass as it is light and easy to work with.

What are the Benefits of Using Polycarbonate for Jug and Container Applications?

Benefits of polycarbonate include:

- Its high-impact resistance makes it almost unbreakable in use.

- It is completely clear, which makes it easy to use for measuring and to see what’s inside.

- You can expect polycarbonate to last for 25 years without deteriorating.

- It is flame retardant.

- Polycarbonate has good abrasion resistance, so it will be long-lasting.

What is Polypropylene?

Polypropylene is also a thermoplastic polymer but differs in its properties from polycarbonates. It is translucent, impact-resistant and robust, and can stand temperatures of between 0℃ and +90℃. Below freezing, polypropylene becomes brittle, and above 90℃, its strength may be compromised.

This plastic can be coloured for different uses and is both dishwasher-safe and microwavable. Polypropylene is often made into fibre by a standard melt spinning process.

Common uses of polypropylene include:

- Plastic parts – from automotive to toys.

- Luggage – Many suitcase manufacturers rely on polypropylene.

- Rope – because of its fibre-like qualities, polypropylene is often used for rope and cordage.

- Carpets – carpeting and fabrics both benefit from this plastic, as do woven bags, packaging and filters.

- Medical – the medical and scientific worlds would be hard-pressed to do without polypropylene.

What are the Benefits of Polypropylene for Jug and Container Applications?

Benefits of polypropylene include:

- It is light and flexible.

- It is resistant to damage by a wide range of chemicals.

- Newer versions have an elastic property making polypropylene even more versatile.

- It costs less to manufacture, so it’s more affordable for large-scale operations.

- It’s BPA-free.

- It is unaffected by bacteria and mold.

- It can be easily coloured for distinction in kitchen applications or branding.

Both plastics have their place within jug and container manufacturing, but which you choose will depend on your individual needs. Here at Pro-Measures, we make all our products from food-grade polypropylene for maximum versatility and easy branding. Due to its resistance to a wide range of chemicals, it is a better choice for measuring jug applications than polycarbonate. Also, being BPA free means easy integration into food contact applications. Not only is polypropylene recyclable (#5 recycle), but we ensure that all our packaging is environmentally friendly as well, so we’re the ideal choice for the eco-conscious brand.

Polypropylene is the perfect material for our products, allowing us to produce high-quality measuring jugs, buckets, cylinders and scoops. They are tough, durable, UV resistant and a cost-effective solution to our customers’ needs, whether in the food industry, chemicals or agriculture. Click here to learn more.